Chuck's Antique Telephone Blog

Is

there a topic that you would like me to cover? Please email

me using the "email & help" button at the top

of this page. Please put "Blog" in the subject line.

Replacing

the covering on a candlestick phone.

February

: It

is wintertime with thoughts of staying indoors and working

on some telephone projects. Collectors often come upon a candlestick

desk telephone where the covering on the base is missing,

torn or just needs to be replaced. Black phones can be found

with a felt-like dark brown cloth while some of the older

phones can be found with a suede leather covering. Nickel

plated phones can be found with the brown covered bases and

early phones with a green covering. Collectors like to use

the felt coverings from old pool tables or suede leather.

For purposes of this blog, I have found an old leather jacket

at a Goodwill Store as noted in the September blog below.

Today

I recovered the base of a Western Electric 20AL manual candlestick

telephone with a piece of leather from the jacket. The base

plate was removed from the phone and the retaining ring taken

off so the old material could be pulled off. To make placing

the material on the base, I cut a template out on a piece

of scrap wood using a dremel and a router as seen in the below

image:

Place

the material over the template and push the base down causing

the material up. Place the retaining ring over the outside

of the material, gathering it to the center and pulling the

edges in as tight as possible. Press the ring into the base

and use the hammer to press it to the bottom thus securing

the material as seen in the next image.

I

used an expensive punch that I bought at a tool store to cut

out the holes for the screws in the bottom of the leather

base. While some cut the holes prior to mounting the cloth

on the base, I find it easier to punch and line up the holes

once on as seen below.

The

last process is to cut off the excess material on the inside

using a razor. Original bases did not have excess material

showing.

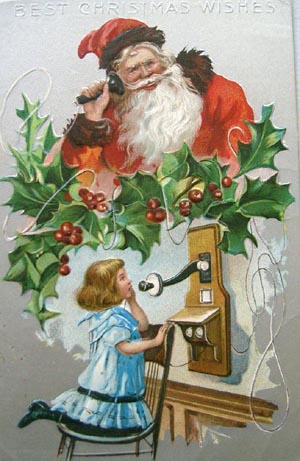

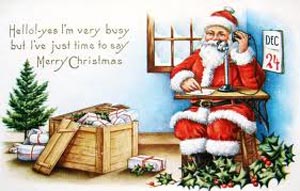

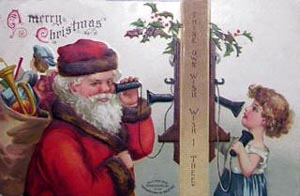

Christmas

with telephones.

December

12. It has been awhile

since I wrote a blog due to my travel schedule this fall.

As we move into this Holiday Season, I was thinking about

the past and how the telephone became an important tool during

this season for connecting with people. This idea showed up

early in the form of post cards and Christmas cards through

the ages. Below are just some of the cards that I have seen

since I have been collecting telephones and memorbilia.

Replacing

the covering on WE 302 feet.

September

12: There

are many occasions when one or more "feet" on a

Western Electric 302 ("Lucy phone"), or a WE 5302

as seen in my April 28th blog below, are worn or torn. Often,

collectors will recover these feet when they want a good looking

telephone to look better. Re coving these is not very difficult

and only cost pennies for each foot for materials. The hardest

part is to find an appropriate covering. Earlier sets were

covered in a suede letter. A good place to find inexpensive

covering is a Goodwill or other thrift shop. Take a couple

of feet in with you and search through clothing to find an

appropriate material. I recently found a nice dark brown suede

jacket that will give me plenty of leather to cover feet and

the bottom plates of candlestick telephones.

The

first step in recovering is to remove the old cover with a

razor blade or knife. Once off the bottom section, you will

notice a small hole on one side of the triangular base. Use

a punch or nail where you have removed the point to punch

out the upper portion that is holding the old covering. In

the photo above, the left hand image is of a damaged foot

taken from a phone. The two images on the right are the resultant

pieces once the covering is removed. Note the hole on the

right in the middle image. This is where a punch or nail can

be inserted to separate the two pieces.

Cut

a thick piece of felt (or a double piece) to be used as a

cushion on the bottom between the leather and the metal in

a triangular fashion as seen below and an appropriate size

of the leather. To make it easier to assemble, I have used

a piece of scrap wood and cut out a template of the foot using

a dremel tool as seen below. Note the pencil marks around

the template. This is so I can line up the piece of leather

when re-assembling the foot.

I

first place the leather over the template

then the felt followed by the bottom of the foot pushing the

entire assembly down as seen in the next photograph:

Fold

the leather over the bottom plate. Using a small blade to

make sure that all of the leather is in the foot, place the

top over and tamp with a hammer until all of the leather and

top is seated. I recommend replacing the covers of all four

feet on the phone for uniformity.

Making

new oak look old

August

28. Once in awhile an oak phone may need a part fabricated.

Most often we find wall phones that are missing a shelf or

part of one. For those that are not handy in the wood shop,

Phonecoinc.com sells new shelves and brackets made out of

new oak. To make the new wood look old to better match the

finish on the rest of the phone, my friend Walt Aydelotte

sent me his method.

Obtain

a box of Oxalic Acid from a hardware store. This is a wood

bleach that will ultimately leave the wood looking a battleship

gray color. The first step is to sand the entire piece of

wood to open the grain and then paint on the oxalic acid liberally,

letting it soak in. Dry overnight and then repeat this process

a second and possibly a third time. Once dried, sand the piece

again making it as smooth as desired prior to staining, using

whatever stains you need in order to match the color you are

trying to duplicate Let the stain dry overnight and apply

a second coat, wiping off lightly so as to not leave any puddles

or globs of stain. Again, let it dry overnight and repeat

the process until the new color matches the old continuing

to "tweak" this coloration until you are satisfied.

Put on a good sanding sealer and after allowing an overnight

drying, sand lightly with 0000 steel wool. Clean the surface

with a tac ray and brush on a clear satin polyurethane. After

allowing to dry thoroughly, sand with a fine grit sandpaper

and tac rag off any sanding dust. Apply a second coat and

sand with 0000 steel wool after it has dried overnight. Walt

uses a final coat of Spray Minwax Fast Drying Polyurethane

Clear Semi-gloss. This can easily "run" so you might

want to do a section at a time, keeping the sprayed surface

flat, parallel to the floor. This stuff sets up in 5-7 minutes,

so not waiting time is required.

Do

not rush this process or cut corner to the the project done

quickly If done properly, the phone will look great and you

will not be able to tell the old from the new

Updated

information on Aug 30: My fellow collector, Tom,

sent me the following information on the above process:

"I've

used Walt's method numerous times with excellent results.

However, there is an alternative process in the finishing

steps that the old oak furniture (and phone makers) used to

avoid problems and speed up finishing. My grandfater went

to work in an oak furniture factory at 12 years old - he was

the first of the old timers to tell me the "tricks".

The key is to alternate solvents in the finishing process.

One of the potential problems of Walt's process is that the

stain, the sanding sealer and the poly may have the same or

similar solvents. That is the reason he advocates allowing

adequate drying time between steps. If you are too hasty (or

in damp weather) the solvent of the next coat can dissolve

part of the previous coat - it has happened to me - I assure

you it is no fun to go back and start over.

To avoid that I use one or more very light coats of shellac

instead of the sanding sealer - the shellac solvent is alcohol

and it does not affect the solvent of the stain and it is

not affected by the solvent of the finish coat. In fact, I've

switched from regular poly to water based poly with better

results - and the final spray coat can be eliminated completely

by using multiple thin coats of poly which dry faster than

solvent based poly.

The shellac coat dries very quickly and allows applicaton

of the final coats earlier than the sanding sealer permits.

No matter which method you use, you need to allow time for

drying thoroughly. Both methods produce excellent results.

This is nothing new - my grandad and his cronies were doing

it this way (or something similar) a hundred years ago."

Removing

paint from a thermoplastic telephone

July

2 . I

was rummaging through a box of old telephones and decided

to restore a dirty Western Electric 354 that had a lot of

paint splatters on it. Quite often these old wall phones were

not taken down when walls were painted and paint splatter

is quite common and difficult to remove. One method that I

found to work is to use automobile brake fluid, an old tooth

brush and a rag. Simply dip the brush in a small container

of brake fluid and gently brush over the affected area several

times. The paint (and the thermoplastic) will soften and the

area is than wiped with the rag. This process will take quite

some time because as the thermoplastic becomes soft, the project

has to be left for awhile to harden. I've had one phone take

all week to clean but it is worth it. On your first try, perhaps

you can practice on a cracked or non-essential phone. After

all of the paint is removed and the plastic on the phone has

been left to harden for several days, normal restoration as

described in my April 28 blog was used to obtain the desired

results as seen below on the right.

Here

are the results of my restoration:

Restoring

a Western Electric model 5302

April

28. I

just located a 5302 and decided to document it's restoration.

The picture on the left is the as found BEFORE restoration

telephone and the one on the right is the same telephone finished

AFTER restoration, complete with modular cord and working.

A

5302 looks almost like the standard rotary phones of the 50's-80's

but upon closer look you see marked differences. Note that

it is shorter than the model 500. In addition, notice that

the dial is a metal 3 inch dial surrounded by a plastic number

shroud. The switch hook area was molded to accommodate either

an F or a G handset. When the phone is opened you will notice

that the base, bells, network and condenser are from a Western

Electric 302. Some have called the 5302 a "transition"

phone between a 302 and a 500 since the housing is a 500-like

over a 302 base. In actuality, this phone was made for the

Bell System to help with the demand for the newer 500 model

and a way for the phone company to save money and use many

of the parts they were collecting when replacing 302's. Was

the Bell System "going green" or saving money?

To

begin the restoration, remove all of the parts. I would highly

recommend taking notes and diagram all of the wiring.

My

first process was to wash all of the plastic parts. Many collectors

place the parts in their dish washer. My wife objects so I

used dish washer detergent and a five gallon bucket of warm

water. The housing is "soft plastic" and most likely

has many dings and scratches. I use fine grit sandpaper and

fine steel wool to sand out scratches followed by Novus 3

and Novus 2 gritted polish (see February 2 for sanding and

the March 25 blog below for polishing).

My

next step was to remove the parts attached to the base to

clean. There are some who like to polish each screw. I don't

tend to be that fastidious but in this case I did use a mild

cleaner and fine steel wool pad on the metal parts. The bells

are brass and were polished. I like to use a common cleaner

such as 409 on the coiled handset cord, recoil it on a dowel

and put a finish polish such as Novus 2 on the exterior. You

can tell the difference between the before and after photos

below:

Remove

the finger wheel, the porcelain number plate and dust barrier.

If the dial was sluggish, clean the pivot points with kerosene

and then re-oil with a small drop using a fine clock oil.

Do not use a WD-40 type lubricant. In short order dust will

collect and the dial will gum up even more. Polish the number

plate and finger wheel. Novus 2 will do a good job on these.

Reassemble

all of the parts and add a modular cord if you plan to use

the phone on today's telephone system.

The

finished telephone will not look as it came out of the factory,

but pretty close. Questions? Email me from the link just to

the right of the moving dial above.

Restoring

the "shine" on plastic telephones

March

25. Perhaps

you have been to a flea market, thrift shop or garage sale

and found a nice old rotary or touch tone telephone that is

dirty and has a number of scuff marks on it. What methods

do you use to get the phone back to a presentable shape?

While

there is no one perfect approach, my method is to first remove

the telephone's housing from the base, remove the handset

capsules and handset cord as well as the line cord. I now

have four pieces of plastic and two cords to clean. If very

dirty, I will take them to the sink and use a detergent on

the parts. Some collectors will place them in the dishwasher

and allow them to go through a cleaning cycle. My wife isn't

as understanding about my collection as much as some collector's

wives are so I can only rely on this "sink method."

Often the cords are quite grimy so I need to spend a lot of

time with a cleaner and an old terry cloth on them.

Once

all of the dirt and grime have been removed, I now use a gritted

polish. Many years ago I became a believer and fan of Novus

plastic polish and scratch remover. This product comes in

a three part system for various types of scratches.

I

start with Novus #3 on a clean soft cloth, usually a piece

of an old terry towel, applying the paste liberally and rubbing

back and forth at right angles to scratches on the surface

of the phone. Keep the cloth saturated with the polish. Continue

polishing until only small scratches are visible. Clean off

any white film left by the polish with a clean cloth.

Using

another clean cloth, apply Novus #2 in a more circular motion

uniformly over the entire surface. Continue until the tan

polish becomes a dry light haze. Using another clean cotton

cloth, buff the entire area. If you can still see scratching,

you should repeat the process. After you are satisfied with

your results, apply Novus #1 liberally using broad strokes.

This is no need to apply a lot of pressure on the cloth.

Your

plastic phone shell, handset, and finger wheel should now

look close to the way it appeared when the telephone man delivered

it many decades ago and worthy of placing in your collection.

You

can also use this process on the telephone cords to clean

and polish them. Once you have finished cleaning the coiled

handset cord, you and reform it on a piece of doweling.

I

do not sell Novus but a quick google search will result in

numerous retail sources.

If

your phone is discolored, Novus will not remove stains. Collectors

use a different process which will be described in a future

blog.

Removing

the finger wheel from a 500 type phone

February

26. There

is another snowstorm occurring here in the Northeast with

about 20 inches now on the ground and it is still snowing.

It is too cold to work in the shop (my garage) so thought

I'd bring a project inside to work on. I decided to replace

the old used number cards on some of my Western Electric rotary

500 sets with new ones that I scanned and printed. I have

used the number card found below. Just copy this image and

print it out for your own use. This is what the number card

looks like on my moss green desk set that I just completed.

I

receive an occasional email from someone asking how to replace

the number card on the telephones with the clear plastic finger

wheel.

The

process is an easy one and the only tool needed would be a

standard paper clip. No, the telephone installer didn't carry

paper clips with him for this task rather he had a pencil-like

tool with a metal tip the size of a paper clip.

Look

at the dial and you you will see a small hole drilled between

the "9" and the "9" finger holes. Open

one end of the paper clip and push it into that hole. Turn

the dial all the way clockwise and push down down on the paper

clip which presses on a metal tab that holds the finger wheel

in place. While holding this "spring" down with

the paper clip, force the dial one more space clockwise. The

finger wheel will come loose and it can be removed from the

phone.

To

put the wheel back in place, put the "0" hole over

the number "9" on the dial and turn the wheel counter-clockwise.

The "spring" will fall back into place in the slot

of the wheel and the finger wheel will stay in place.

Looking

for a number card to place on your dial? Below is one from

the proper era that can copied (right click) and printed.

It should print at the proper size.

Nickel

Plating Phone Parts

February 4. Do you have a telephone with

some nickel parts where the nickel plating is shot? The choices

we face are limited. We can leave the nickel as found; strip

and buff the part back to it's brass base (old phones were

never supplied in bare polished brass); paint it black; have

the part professionally plated; plate it yourself.

Self-plating

is not difficult. Many collectors use an inexpensive Texas

Platters Nickel Kit. This is available from Texas Platters

Supply, 2453 W. Five Mile Parkway, SGN., Dallas, Texas 75233.

Phone (214) 330-7168. The kit consists of a plating brush,

wire, clips and a small jar of copper and nickel plating jell.

About

ten years ago, fellow collector, Steve Brink took his old

worn nickel plated Stromberg Carlson "oil can" phone

and re-plated it using the Texas Platters' kit. The results

were quite stunning. Those who saw the phone at the Abilene

Telephone Show were amazed at his results. The photos below

do not show the actual beauty of Steve's accomplishment:

The

most difficult part is the preparation of the metal parts.

It is best to dissemble the parts of the phone, taking careful

notes as to how to re-assemble. All of the old nickel must

be removed. This can be accomplished with 320 grit sand paper

(I like to use emery paper). For hard to reach and detailed

areas a dremel tool with a brush attachment and polishing

compound would be appropriate. For any pitted areas, use a

220 grit sand paper. Keep progressing using higher and higher

grit sandpaper, each time moving up 100 or so grit increments

until you reach 1000 grit. At the higher levels of grit, I

like to use the "wet sandpaper." Once at this level,

I use a buffing wheel to polish the brass so that it is mirror-like.

If you see any scratches, go back over them with the sandpaper,

finding the grit that will remove the scratch and work back

up the grit scale. The brass should now be consistently "mirror-like."

It would be best to go over all the parts with a commercial

cleaner such as Semi-Chrome and buff with a very soft cloth.

Once

the metal has been prepared, plating can begin. Just prior

to plating, clean off the surface with a non-lotion soap to

remove any oil that may be on the parts. Some have used a

wash of denatured alcohol very successfully. Using the instructions

that come with the plating materials, connect the negative

side of a battery (3 volts DC are required. This can be done

with two 1.5 dry cells or a three volt DC power supply. I

use a universal AD/DC adaptor turned to 3-4.5 volt level.

I've cut off the pin on the end of the wire and connected

the clips that are supplied with the kit) to the part to be

plated. The positive side clip gets attached to the handle

of the plating brush. Dip the brush into the supplied solution

and "paint" on the plating. I have to clean the

brush often as the metal comes out of the jell.

Once

plated, clean off any excess with soap and buff with a cloth.

Note:

the kit consists of two compounds, copper and nickel. It is

best to copper plate and then nickel over the copper. If you

don't like the results on a piece, the plating can be removed

with sandpaper.

Cleaning

Nickel

February

2. Ah, Ground Hog's Day! Now that we will still have

a lot of winter ahead of us, according to the little critter

that saw it's shadow this morning, it is time to think about

cleaning up some of the old telephones we have sitting around

the house. For my first blog entry, I thought of that old

nickel that we see on the early stick phones and on the plated

bells and transmitter faceplates on the old wooden phones

that might be blackened by age. Is there a "safe"

way to clean the nickel?

If

the nickel appears to be in decent shape, probably the best

way to clean it is to use common household ammonia. After

removing the nickel part from the phone (remove the transmitter

parts from the faceplate first), immerse it in a small container

with the ammonia. I often leave the part immersed for several

hours. You will see the ammonia turning a bluish color as

it removes tarnish. Buff the nickel with a soft cotton rag.

I've found that my old cotton tee-shirts work really well

for this task.

If

the nickel is too far gone, ammonia will not help and the

best suggestion would be renickeling the part. I'll give a

few hints on this process in my next blog.